D.S.O. Manufacturing has been in business since 1947. We continue to make improvements to solve our customers demands. With our skilled labor force and engineering expertise we are able to manufacture products and meet customer demands.

The goal at DSO has been to be our customer’s partner in world class manufacturing technology. Our philosophy is based on honesty, integrity and a no non-sense approach to supply our customers with the quality they expect.

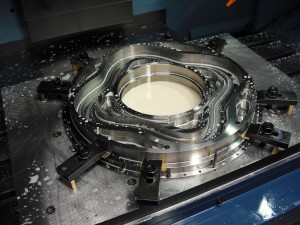

ES1000 Matsuura

Our commitment to utilizing the most advanced machine tool technology available today , gives our customers access to machining their products in an environment that surpasses our competition. We update our equipment continuously to provide the highest level of service.

DSO’s specialty is machining close tolerance parts from exotic and specialty alloys to a level that exceeds our competition and customer requirements. Some alloys we machine include, 718 Inconel heat treated, Nitronic , 300 and 400 series stainless steel, Titanium, Tungsten, ToughMet, Copper and Plastics among others.

I400 Integrex

DSO’s capacity includes 4 Mazak multi-tasking machines which have a lathe platform with a full milling spindle. Our lathe department consists of 7 CNC turning centers that have a work envelope to encompass parts from 28.4″ diameter up to 78.7″ between centers. Our 4 axis vertical Matsuuras can machine 21″ x 23″ x 40″ requirements with high pressure through the spindle coolant. Seven Makino horizontals round out our inventory of machine tools. With glass scales and through the spindle coolant for high production, these machines give us the ability to produce parts in the 39″ x 31.5″ x 24.8″ class.

ZEISS Contura

DSO’s Quality Department ensures your parts are manufactured to the highest standards utilizing our Zeiss Contura CMM.

With our highly skilled work force and state of the art technology, DSO will fulfill your complex machining requirements with both high quality and on time delivery.